rom Prototyping to Mass Production – How Automotive Wire Harnesses Are Made

Every vehicle relies on a complex network of wire harnesses — and every harness goes through a rigorous process before reaching the assembly line. From engineering evaluation to final packaging, each step plays a vital role in ensuring the harness is safe, durable, and fully compliant.Let’s walk thr

The Role of Connectors and Terminals in Automotive Wire Harness Reliability

Introduction A wire harness is only as strong as its weakest connection.Connectors and terminals form the critical interfaces that link wires, sensors, and modules. Their reliability directly impacts vehicle performance, especially in environments with vibration, temperature fluctuation, and moistur

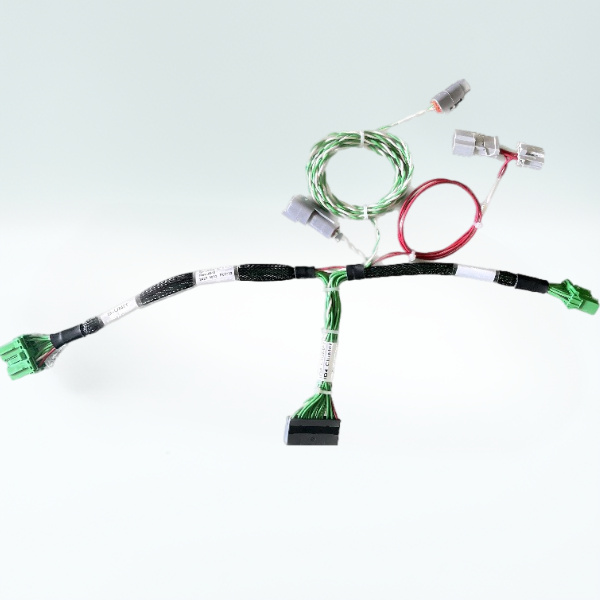

The Complete Guide to Automotive Wire Harness Design and Engineering

Introduction Automotive wire harnesses are the backbone of every modern vehicle, connecting thousands of electrical and electronic components. A well-designed harness ensures seamless communication, power transmission, and long-term reliability — while a poorly designed one can cause performance iss

How Automotive Wire Harness Testing Ensures Safety and Reliability

Introduction In the automotive industry, wire harnesses are the nervous system of modern vehicles — transmitting power and signals between every electronic module. A single faulty connection can lead to serious consequences, from minor electronic malfunctions to catastrophic system failures. That’s

Get an Instant Quote Now

One-Stop OEM/ODM Solutions

Want to Know More?

Contact us for brochure, quotation, or visit arrangement.